our solution

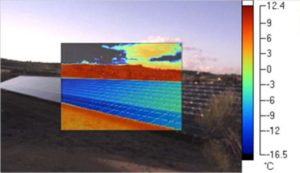

use of the drone

Better results, precise and in less time: acquisition of 1 MW of plant data in less than an hour of overflight

better quality

Being able to perform data collection in the central hours of the day (therefore maximum reliability of the results)

lower cost

Only one qualified person is applied in the field for less time (lower cost than a traditional ground inspection)

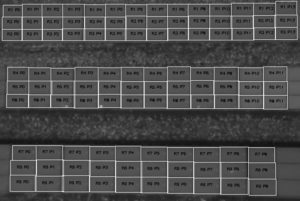

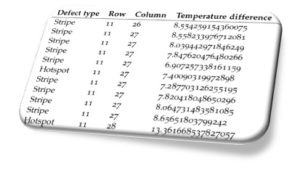

software Solarinspection

Faster analysis (1 MW in just over 30 minutes) and higher quality, with precision and no human error (top reliability)

why do an inspection

Investors ask themselves two fundamental questions: how much electricity will generate the photovoltaic system and how well the photovoltaic system works. The energy generated by the photovoltaic system in a reference time, for example within a year, depends on solar irradiation and on the efficiency of the modules. The theoretical yield of the photovoltaic system is the theoretical annual production of energy, the direct current side of the modules, which depends on the incident sunlight and the nominal efficiency of the module. The performance ratio (or quality factor) is the ratio between the current yield and the theoretical yield and takes into account the pre-conversion losses; losses in the inverter (after which energy is produced in the form of alternating current); thermal losses and losses in the conduction of electricity. It is therefore extremely important to measure the quality factor during plant operation to monitor its progress.

About 5% of the total losses are counted. In particularly dry regions, the loss due to dust accumulation can even reach 25%.

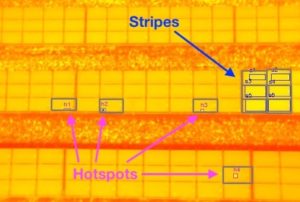

Efficiency of converting photons of light into moving electrons. The percentage of thermal losses due to local overheating (hot spot) is estimated at around 8%.

Depend on losses in electrical components such as wiring, inverters and transformers. Losses in the electricity system are estimated at around 14%.

our added value

The Pilot

The drone

thermal sensor

RGB sensor